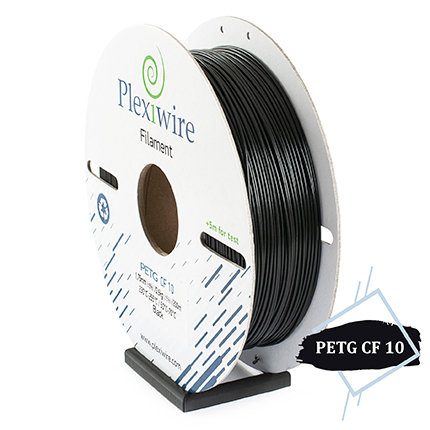

PETG CF 10

Plexiwire PETG CF 10 is a 10% carbon fiber petg filament that combines the strength of PETG with the additional properties of carbon. This 3d printer filament material is 25% stronger than standard PETG, making it ideal for demanding engineering applications. The carbon fibers not only strengthen the material, but also provide superior layer adhesion, making the print result even more resistant to separation and peeling. Compared to conventional PETG, PETG CF 10 is characterized by even lower shrinkage, allowing parts to be produced with high precision. A special feature of this filament is its unique surface structure after printing, different from the results obtained with unfilled materials. Thus, Plexiwire PETG CF 10 is the ideal solution for demanding professionals looking for a combination of strength, durability, and quality in 3D printing.

- Improved strength - Thanks to the addition of carbon fibers, PETG CF10 is 25% stronger than standard PETG.

- Excellent layer adhesion - carbon fibers strengthen the bond between layers, preventing them from peeling.

- Even less shrinkage - compared to conventional PETG, CF10 provides more consistent print results without warping.

- Engineering applications - the material is ideal for creating parts designed for stresses and demanding environments.

- Unique texture - the surface of products printed with PETG CF10 is characterized by a distinctive, unique pattern.

- Versatile application - PETG CF10 is ideal for both professional 3D printing needs and amateurs who want to achieve professional quality in their products.

CHARACTERISTICS OF PLEXIWIRE PETG CF 10

- EXTRUDER TEMPERATURE

- 230°С - 255°С

- PLATFORM TEMPERATURE

- 70°С - 80°С

- PRINTING SPEED

- 30 - 80 mm/s

- FILAMENT

- 1.75 мм

- COILS

- 100 / 200 m

- WEIGHT

- 0.3 / 0.6 кg

- Black

- Print temperature settings - PETG CF10 containing carbon may require a slightly different temperature setting compared to pure PETG. Start with the recommended settings and make adjustments based on results.

- Protect against mechanical damage - Due to the presence of carbon fibers, the filament may be more sensitive to bending or shock loads. Gentle handling will extend the life and maintain the quality of the material.

- Use special nozzles - carbon fibers can quickly wear out standard metal nozzles. Use nozzles made of hardened steel or other stable materials to lengthen the life of the extruder.

- Proper storage - like many filaments, PETG CF10 is sensitive to moisture. Store in an airtight container with silica gel or in specialized dry filament boxes to prevent moisture absorption.