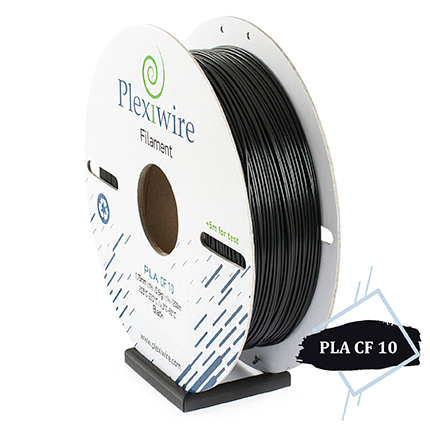

PLA CF 10

Plexiwire PLA CF10 is a 10% carbon fiber filament that combines PLA’s strength with carbon’s enhanced characteristics. This material is 25% stronger than regular PLA, making it ideal for complex engineering and functional printing applications. Carbon fibers reinforce the material and provide excellent adhesion between layers, making products resistant to separation and peeling. Unlike standard PLA, PLA CF10 exhibits lower shrinkage and improved brittleness characteristics, making it less brittle than standard PLA. What makes this filament special is its unique surface texture after printing, allowing it to be used for various designs. Thus, Plexiwire PLA CF10 is an excellent choice for professionals looking for a combination of strength, durability, high quality in 3D printing, and unique design.

- Improved mechanical properties: thanks to the addition of carbon fibers, PLA CF10 is 25% stronger than standard PLA.

- Superior layer adhesion: Carbon fibers strengthen the bond between layers, preventing peeling.

- Minimized shrinkage: Compared to traditional PLA, CF10 provides more consistent print quality without warping.

- Engineering applications: Compared to conventional PLA, PLA CF10 is ideal for high-stress and demanding applications due to its improved mechanical properties.

- Unique texture: Products printed from PLA CF10 have a unique and distinctive surface pattern.

- Wide range of applications: PLA CF10 suits 3D printing professionals and enthusiasts seeking high-quality work.

CHARACTERISTICS OF PLEXIWIRE PLA CF 10

- EXTRUDER TEMPERATURE

- 190°С - 220°С

- PLATFORM TEMPERATURE

- 50°С - 70°С

- PRINTING SPEED

- 60 mm/s

- FILAMENT

- 1.75 мм

- COILS

- 100 / 200 m

- WEIGHT

- 0.3 / 0.6 кg

- Black

- Printing temperature: Set the extruder temperature between 190-220°C. When using carbon fillers, temperature settings may differ from standard PLA, so experimenting to find the optimal temperature may be helpful.

- Heated platform: While PLA does not usually require a high platform temperature, for PLA CF10, it is recommended to set the platform temperature in the range of 60-70°C for better adhesion and to prevent warping.

- Print Speed: Depending on the part's complexity, it is recommended to set the print speed in the range of 40-60 mm/s. Slower printing can provide better surface quality and better adhesion of layers.

- Special attention to nozzle: Since carbon fibers can cause rapid wear on standard metal nozzles, it is recommended to use hardened steel nozzles or other wear-resistant materials to increase nozzle life and ensure consistent print quality.