Nylon for 3D printing

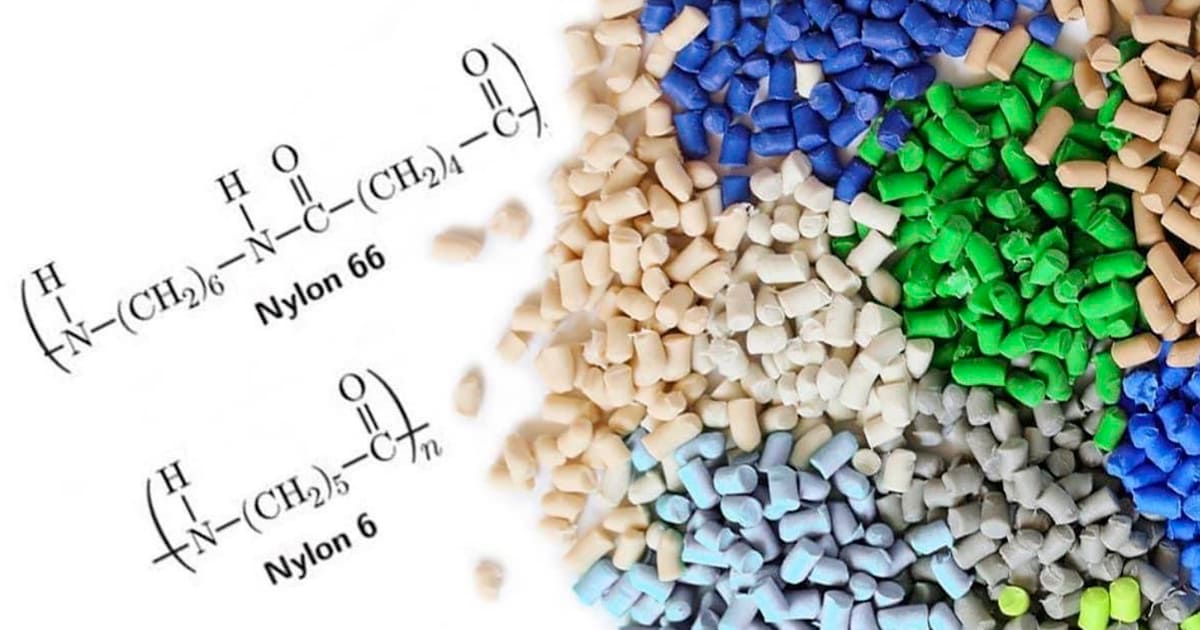

Nylon is a versatile group of polyamide-based thermoplastic polymers that were initially created to replace silk. Under the name “Nylon,” you can find different filaments that differ slightly in composition and have other properties. Nylon filaments demonstrate great versatility and characteristics, allowing you to create solid and flexible objects with a beautiful silky surface.

This explains why this type of plastic is most often used in such 3D printing industries as prosthetics, robotics, mechanics, and manufacturing of functional non-metallic parts, belts, gears, handles, waterproof products, and housings. It is an ideal material for manufacturing parts with a ready-made purpose. This type of plastic also meets most of the requirements of engineers, designers, and manufacturers. And it is easy to buy, it is standard.

What are the properties and where to buy nylon for a 3D printer?

Nylon is highly resistant to impact and abrasion and has a low coefficient of friction. It is also characterized by corrosion resistance to alkalis and organic chemicals.

The final object will be solid and wear-resistant if nylon yarn is used for thick structures with a high filling density. When faced with a load, such parts will have excellent impact resistance. You can get flexible, elastic objects using this filament for thin parts.

Nylon fibers are more difficult to work with than PLA. Nevertheless, any 3D printer can print with this material, provided that the print temperature is maintained at a high level (220-270°C), the table is heated, and even the body is heated to avoid deformation. The latter is a recommendation but not a prerequisite. It’s worth noting that the nylon filament on the spool is flexible, so it can cause jams, especially if the 3D printer is programmed for high feed and print speeds.

As a powdered nylon, this filament absorbs quite a bit of moisture, which should be considered when storing the filament or printed parts. However, this characteristic makes it easy to dye items made of nylon with dyes for synthetic fabrics – the result will be long-lasting.

The advantages of nylon include the following characteristics:

- High strength and durability.

- Better resistance to temperature, wear, ultraviolet radiation, and chemicals.

- The ability to create both rigid and flexible parts.

- Easy to paint and coat.

- Excellent surface finish.

Among the disadvantages of this type of plastic are the following:

- High moisture absorption, so the material requires special storage before 3D printing.

- Printed parts slightly change their properties when exposed to air without a topcoat.

- More challenging to print compared to ABS or PLA.

- There is a potential risk of shrinkage as the temperature in the printer decreases.